Packaging machine for gusset, quad seal, flat bottom bags

- 1.

What Is a Gusset Bag?

- 2.

What Is a Quad Seal Bag?

- 3.

What Is a Flat Bottom Bag?

- 4.

How Are These Bag Types Related?

- 5.

Introducing ZOMUKIKAI’s Gusset Bag Packing Machine

- 6.

Key Highlights of the ZOMUKIKAI Gusset Bag Packing Machine

- 7.

Typical Technical Specs

- 8.

Why Choose ZOMUKIKAI?

- 9.

Let’s Build Your Ideal Packaging Line

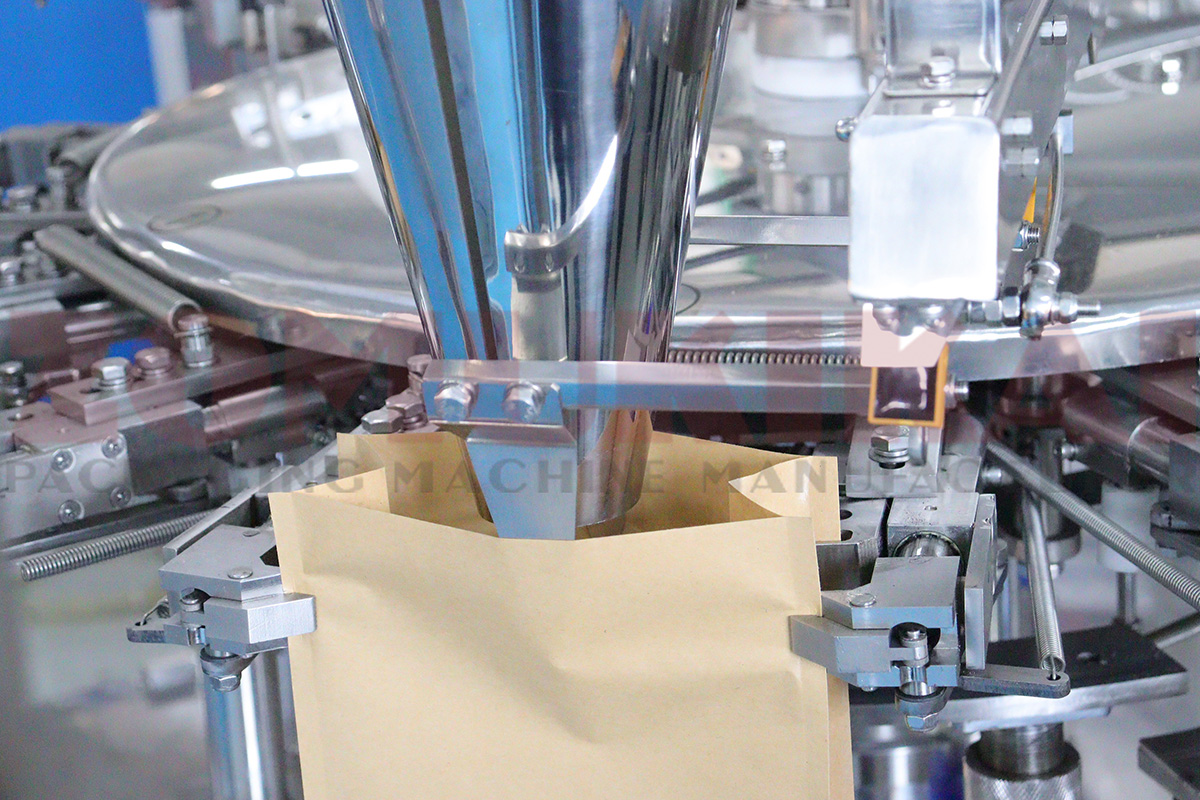

Gusset bag packaging machine

What’s the Difference Between Gusset Bags, Quad Seal Bags, and Flat Bottom Bags?

Discover ZOMUKIKAI’s Versatile Gusset Bag Packing Machine That Handles All Three

In today’s competitive packaging industry, choosing the right bag type goes far beyond aesthetics. It affects product protection, shelf presence, storage efficiency, and even consumer perception. Among the most commonly used flexible packaging formats are:

• Gusset Bags

• Quad Seal Bags

• Flat Bottom Bags

While they may look similar at first glance, these three bag styles have distinct structural and functional differences. In this article, we’ll break down the unique features of each bag, how they’re related, and most importantly — how ZOMUKIKAI’s Gusset Bag Packing Machine offers a smart, flexible solution capable of handling all three bag types with one powerful system.

A gusset bag is a traditional yet versatile packaging format that features side folds (gussets) running from top to bottom. These gussets allow the bag to expand when filled, increasing capacity without altering the width of the front or back panel.

✅ Key Characteristics:

• Gussets on both sides

• Expandable structure to accommodate more volume

• Typically made from laminated film for durability

• Ideal for bulk items: rice, grains, coffee beans, pet food, powders, etc.

• Can be heat-sealed and customized with zippers, tear notches, and valves

A quad seal bag, also known as a four-corner seal bag, builds on the gusset bag structure. It features four vertical seals — one on each corner of the bag — which gives it a more box-like, upright shape and enhanced durability.

✅ Differences from Gusset Bags:

• Includes four side seals instead of two

• Provides more structure and rigidity

• Offers better stacking ability for shipping or display

• Looks more premium and retail-friendly

• Often used for coffee, pet food, and premium snacks

A flat bottom bag, also known as a block bottom or box pouch, takes things a step further. It combines the gusset and quad seal structure, but also adds a completely flat base, allowing it to stand perfectly upright like a box.

✅ Key Features:

• Has five panels: front, back, two gussets, and a flat bottom

• Provides the largest branding area (printable on all sides)

• Excellent for display and shelf visibility

• Most structurally stable of the three

• Preferred for high-end food, nutrition, and coffee products

How Are These Bag Types Related?

The three bags are part of a progressive design evolution:

Gusset Bag

↓ (with 4 corner seals)

Quad Seal Bag

↓ (add a flat bottom panel)

Flat Bottom Bag

• All quad seal bags start from gusset bags

• All flat bottom bags build upon quad seal designs

• Each level adds more structure and visual appeal

So if you can pack a gusset bag efficiently, you’re already halfway to handling quad and flat bottom bags — with the right equipment.

Introducing ZOMUKIKAI’s Gusset Bag Packing Machine

One Machine. Three Bag Types. Endless Possibilities.

At ZOMUKIKAI, we understand that modern manufacturers need versatile, future-ready equipment. That’s why we designed our Gusset Bag Packing Machine not just for gusset bags — but with the flexibility to handle pre-made quad seal bags and flat bottom bags as well.

Thanks to a reengineered bag clamping system and smart opening and positioning mechanisms, the machine can adapt to multiple bag shapes with minimal changeover.

Key Highlights of the ZOMUKIKAI Gusset Bag Packing Machine:

• ✅ Multi-bag compatibility: Handles gusset bags, quad seal bags, and flat bottom bags with ease

• ✅ Fully automatic: Bag pickup, opening, corner forming, filling, sealing — all in one workflow

• ✅ Supports various products: Powders, granules, solids, and liquids

• ✅ Customizable modules: Zipper closures, hanging holes, nitrogen flushing, dust collection, and more

• ✅ Hygienic & durable: Made with SUS304 stainless steel (optional SUS316 for food & pharma)

• ✅ Easy operation: Touchscreen control, fault alerts, memory for multiple bag recipes

| Model | ZP-8R180M |

|---|---|

| Bag width | 80-180mm |

| Bag length | 100-400mm |

| Bag types supported | Gusset bag, Quad seal bag, Flat bottom bag |

| Packaging speed | bags/min (depends on product) |

| Power supply | 220V/380V, 50/60Hz |

| Frame & contact parts | SUS304 stainless steel |

With over a decade of packaging innovation, ZOMUKIKAI has earned the trust of food, pharmaceutical, and chemical producers around the world. Our solutions are designed for:

• ✅ Adaptability to evolving product formats

• ✅ Ease of integration with upstream and downstream automation

• ✅ Minimal downtime and quick changeovers

• ✅ Remote technical support and global service coverage

• ✅ Customized solutions based on your product and packaging needs

Applications:

Our Gusset Bag Packing Machine is already used in:

• Coffee and tea packaging

• Pet food and treats

• Rice, beans, grains

• Protein powders and nutrition supplements

• Fertilizers and agricultural products

• Snack foods and candies

Let’s Build Your Ideal Packaging Line

Whether you’re packaging classic gusset bags or exploring quad seal and flat bottom styles for better market impact, ZOMUKIKAI’s Gusset Bag Packing Machine gives you the power to adapt and grow — without needing a separate machine for every bag type.

Get in touch for a free consultation, sample testing, or machine demo. Let’s upgrade your packaging line — the smart, flexible, ZOMUKIKAI way.